There are nearly 300,00 industrial facilities in the U.S., many of which are still using outdated lighting technology.

But that’s starting to change. Industrial customers are looking to modernize, and many of them are considering the switch to LED lighting throughout their entire facility.

While this is excellent news, it’s not as simple as replacing the bulbs at home. Industrial and manufacturing environments are not gentle: Temperatures can range from sweltering to freezing, with the air full of moisture, vapors and particles that can penetrate fixture housing.

In industrial settings, switching to LED lighting can save a fortune in energy costs – but the lighting has to be as tough as the people who work there.

Get the E-book: Guide to Selling Industrial Lighting

That’s why we’ve created this guide to industrial LED lighting. Whether you’re a contractor, facility manager, or you simply want to learn more about LED lighting in industrial settings, in this guide we’ll show you:

- The signs that it’s time to make (or propose) a switch to LED lighting

- The benefits of LED lighting in industrial environments

- The industrial LED lighting fixtures that will facilitate top performance, improve safety and so much more

Skip Ahead: Browse Industrial-Strength Litetronics Products

Ready? Let's get started!

To jump to a specific section, click on one of the links below.

Signs It’s Time for an Industrial LED Lighting Upgrade

Poor Visibility

There are already plenty of safety hazards to manage within an industrial facility without the added risk of poor visibility.

There are already plenty of safety hazards to manage within an industrial facility without the added risk of poor visibility.

Dingy lighting makes even everyday activities riskier – and inadequate visibility can be especially dangerous in areas like staircases, catwalks, and high traffic corners with caution signage.

The metal halide lamps often used in high bay fixtures in warehouses and factories can burn out and need to be replaced. But occasionally, when the lamp burns out, the tube inside these lamps explodes. If this happens on an open fixture, employees or flammable materials below the lamp can be showered with molten glass, potentially leading to serious injury or fire.

Related Reading: Hazardous Location Lighting Guide

Then there are regulations on industrial facility lighting from the Occupational Safety and Health Agency (OSHA). OSHA sets minimum requirements for common commercial installations in foot-candles of illumination or lux levels:

- Warehouses, walkways and exits: 100 lux

- Factories and workshops: 750 lux

- Warehouse loading bays: 300–400 lux

- Warehouse aisles: 100–200 lux

If the current fixtures within an industrial facility don’t produce adequate light to comply with these lighting safety regulations, the business could be in danger of OSHA penalties or big fines.

Additionally, certain types of work being done in the facility may demand specific light levels and temperatures. For instance, old fixtures may not provide the bright light needed to ensure proper cleanliness in food preparation facilities, or they may create glare in locations where computers are used.

High Energy and Maintenance Costs

Fluorescent, incandescent, CFL and metal halide fixtures are widely used in industrial facilities – and poor energy efficiency of these fixtures leads to high utility bills. Approximately 1 billion linear fluorescent lamp (LFL) fixtures and luminaires are installed in commercial and industrial facilities in the U.S., costing companies around $27 billion annually.

Fluorescent, incandescent, CFL and metal halide fixtures are widely used in industrial facilities – and poor energy efficiency of these fixtures leads to high utility bills. Approximately 1 billion linear fluorescent lamp (LFL) fixtures and luminaires are installed in commercial and industrial facilities in the U.S., costing companies around $27 billion annually.

Our e-book, How to Sell a Skeptical Customer on LED Lighting by Proving ROI, provides formulas you can use to put hard numbers on the cost of manhours for maintenance of outdated fixtures.

Our e-book, How to Sell a Skeptical Customer on LED Lighting by Proving ROI, provides formulas you can use to put hard numbers on the cost of manhours for maintenance of outdated fixtures.Older fixtures also prevent companies from taking advantage of the latest lighting technologies, such as sensors, controls, and adjustable wattage fixtures that give the customer much greater control over how the lighting is utilized. The savings can be significant, particularly when considering that many industrial facilities run operations 24 hours a day, 7 days a week.

Meanwhile, the shorter (and often unpredictable) life span of older bulbs means maintenance staff is often on a near-constant cycle of bulb replacement. This maintenance labor is a frequently overlooked area of current costs.

There is also the cost in productivity when burnt-out fixtures disrupt work in an industrial setting, which can halt production times and even cause harm.

Related Reading: LED Lights for Industrial Use: The Risks of Outdated Lighting

Benefits of LEDs for Industrial Environments

Less Maintenance and Disruption

It’s simple: Products that don’t need to be replaced as often won’t require as many manhours to maintain. And lighting maintenance often requires ladders and lifts, which can disrupt operations.

It’s simple: Products that don’t need to be replaced as often won’t require as many manhours to maintain. And lighting maintenance often requires ladders and lifts, which can disrupt operations.

The right LED lighting can last between two and 10 times as long as older lighting options, meaning less frequent maintenance for every year of the LED’s lifetime.

The half-life of a traditional incandescent bulb is about 2,000 hours. Fluorescent is better, with a half-life of up to 36,000. But fluorescent bulbs require a warmup period and become less efficient over time because they need more voltage to produce the same lumen output. The half-life of LED increases to around 50,000 hours. With this dramatically longer life span, lighting budget dollars go farther, protecting the investment for the long term.

Litetronics LED lights deliver a standard 100,000 hour product lifespan, which is typically double the lifespan of other LEDs. Our products are also backed by a 10-year warranty, so our customers know they’ll get the full lifespan of the fixture.

Additionally, less time spent on “bulb patrol” frees up maintenance tech time, allowing attention to more important projects. And facilities that aren’t constantly disrupted for maintenance mean more productivity and output for the company.

Better Performance for Safety

Better lighting in danger areas like stairwells, near machinery, or on platforms can prevent injury and any resulting employee downtime (or workman’s comp payouts).

With LED technology, your industrial customers can use beam angles to get light right where it is needed for a task. Healthy, rested employees are also less likely to get injured on the job. And LEDs don’t create glare that causes eyestrain and fatigue.

Related Reading: The Benefits of Selectable LED Color Temperature & Wattage

Advanced features like occupancy sensing can ensure employees walking in a storage room or forklifts accessing the back of the warehouse have lighting to safely navigate without having to light those spaces all day.

Energy Savings

Upgrading to LEDs can cut an industrial facility’s lighting energy load by at least half because the older incandescent and fluorescent lighting fixtures they replace are much less energy efficient.

Upgrading to LEDs can cut an industrial facility’s lighting energy load by at least half because the older incandescent and fluorescent lighting fixtures they replace are much less energy efficient.

For example, one beverage company with a 240,000 square-foot manufacturing facility switched to LED and reduced lighting energy consumption from 133,000 watts to 44,000 watts, a 67% energy savings. That can have significant ripple effects to other areas of the operation and to the business’ profit margin.

A lower lighting energy load may even allow the operation to add new equipment without overloading the electrical system. LED fixtures also are not heat generators like older fixtures. That means a decreased load on the HVAC systems trying keep the facility cool in warmer climates or summer months.

Reduced Carbon Emissions

Many large companies are now setting ambitious goals for reducing their carbon footprint. Often, these goals are part of a larger corporate responsibility or sustainability drive that provides wide-ranging benefits to the business, like:

Many large companies are now setting ambitious goals for reducing their carbon footprint. Often, these goals are part of a larger corporate responsibility or sustainability drive that provides wide-ranging benefits to the business, like:

- Lower operating cost from reduced energy usage

- Pleasing consumers who prefer products and services from green companies

- Compliance with the growing number of climate regulations

- Responding to pressure from environmentally-conscious investors

- Improved brand perception and customer loyalty

Companies looking to drastically reduce their carbon footprint can’t just stop production. And replacing inefficient production equipment can be a complex and lengthy process.

But lighting? Lighting is an easy and quick way to put a dent in any industrial facility’s carbon footprint. According to the Department of Energy, by 2035, the majority of lighting installations are anticipated to use LED technology, and energy savings from LED lighting could top 569 terawatt hours annually by 2035. The more industries get on board with LED lighting, the fewer tons of CO2 will be put into the air.

Emergency Preparedness

When power fails in a large space like an industrial facility, LED emergency lights are better suited to the needs of the space and getting people out safety.

Depending on the height of the ceiling in a space, like a shop floor in a manufacturing facility or a warehouse, it can be hard to navigate long, tall aisles to find the closest exit without strong overhead light. An LED emergency light for high ceilings can reach the minimum one-foot candle requirement at floor level from 30-40 feet up.

If the facility needs options to outfit a building that doesn’t already have emergency lighting, a good option is adding a backup batteries to LED fixtures, getting a better quality emergency light for safer egress.

Related Reading: Emergency Ready: A Contractor’s Guide to Commercial Emergency Lights

Examples of Industrial LED Lighting Fixtures

Lighting vast industrial spaces like manufacturing facilities, warehouses, and factories takes a lot of illumination.

Lighting vast industrial spaces like manufacturing facilities, warehouses, and factories takes a lot of illumination.

These spaces have plenty of vertical and horizontal space and often high shelving and machinery that can cast shadows – so, they need powerful fixtures that can provide the appropriate foot-candle levels and light quality to reach into every corner.

Fortunately, there is a wide range of options today for every industrial setting, no matter how challenging. To illustrate, here is an overview of our own selection of industrial LED ceiling lights, add-ons, and retrofits that can make converting an industrial space easier and more cost-effective.

Replacement Fixture Options

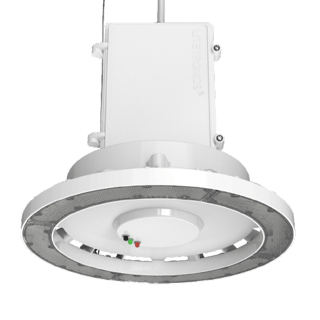

| LED Round High Bay PL – A premium fixture for ceilings ranging from 20′ to 40′ that operates at 140 LPW with lumen levels ranging from 16,100 to 33,600 for focused, even light at a 110° beam angle ensuring coverage from fixture to fixture. |  |

| LED High Bay SL – A basic, performance driven LED fixture that delivers 130 lumens per watt, with lumen levels ranging from 13,000 – 26,000, a frosted lens that ensures soft, even illumination, and a rated life of 50,000 hours. |  |

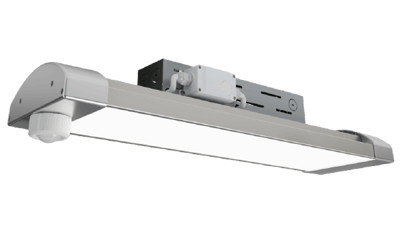

| LED Linear High Bay – This fixture delivers up to 160 lumens per watt, providing optimal light while using minimal energy and it can be used with or without a sensor. |  |

| LED Vapor Tight Slim Strip – These indoor/outdoor LED fixtures deliver guaranteed protection from dust, high pressure wash downs and even total submersion for up to 30 minutes. |  |

| Hazardous Location LED Lighting – This LED High Bay is Class I, Division 2 rated and T4-rated and comes with a corrosion resistant coating and a IP66 rating. |  |

| Food Grade LED NSF High Bay – This LED High Bay offers a heightened level of sanitation from a smooth outer shell that eliminates contamination and bright light through a thinner, lighter, durable polycarbonate lens. |  |

Great LED Lighting Add-Ons for Industrial Settings

|

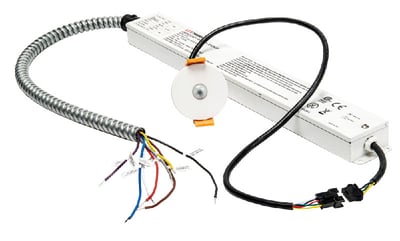

LED Emergency Battery Backup – Get 90 minutes of light during power loss from this LED Emergency Battery Backup that offers monthly automatic self-testing and visible indicator lights to signal operational status. |

|

Litetronics has designed a fixture specifically for high-ceiling applications in industrial facilities that need to update to meet code. It can be easily wired into an industrial setting which makes it a great product to bridge that gap.

| LED Emergency Light for High Ceilings – This emergency light can be mounted up to 40′ and at 30W delivers 4,000 lumens for 90 minutes or at 21W delivers 2,800 lumens for 120 minutes. |  |

Retrofit Fixture Options

Most industrial facilities include administrative spaces like offices, conference rooms and showrooms in addition to large workspaces. You may want to consider retrofits for these types of spaces within an industrial building.

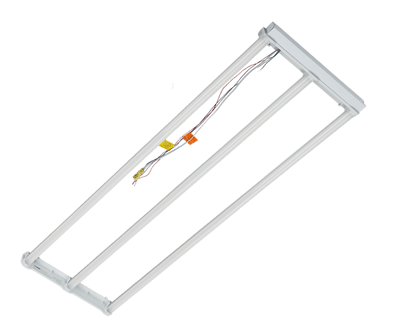

| LED Magnetic Retrofit – Installing in minutes, this fluorescent to LED conversion kit delivers up to 157 lumens per watt and comes in four models that offer adjustable wattage, 0-10V dimming or tri-level dimming and sensor compatibility. |  |

| LED Light Panel Retrofit – This grid ceiling LED panel retrofit comes with advanced features to maximize energy savings and improve occupant experience. | |

| LED Volumetric Retrofit – This retrofit kit mounts between the grid rail and the existing fluorescent troffer, reducing waste and labor by eliminating the need to open the ceiling plenum. |

Why Litetronics Is the Best Choice for Industrial LED Lighting Projects

Industrial facility retrofits are big projects.

Industrial facility retrofits are big projects.

You’ll want to know the manufacturer you’re working with has your back with the product, logistics, and support to carry you through. As a recognized industry leader with more than 50 years of experience, no one knows more about lighting industrial facilities than we do.

Most Litetronics LEDs come with a 10-year, 100,000hr warranty. Contrast that with older or inferior products with only a three-year warranty: A longer lasting product guarantees your customer will get more time between bulb changes, more productivity and more savings.

Litetronics’ LED fixtures come install ready. That’s because we put as much thought into the ergonomics of the install as the quality of the light. Our lights are as lightweight as possible to enable easy handling. An install in a sprawling industrial facility is a heavy lift and installer will appreciate a lighter fixture.

Capture this Industrial-Strength Opportunity

LED lighting in industrial settings is a regret-proof decision.

Not only does LED light provide brighter, cleaner and safer lighting in hazardous industrial settings, it also reduces energy usage – making it a budget-smart and green initiative.

Want to learn more about how LED lighting transforms workspaces while improving efficiency? Read some of our success stories.

Want tactical guidance on how to sell LED lighting to industrial customers? We’ve got you covered with our e-book: Guide to Selling Industrial Lighting.